1. Zinc wire manufacturing process

- metallurgical manufacturing and forming.

2. Raw material zinc ingots

- LME Grade(LME), n-a grade of zinc containing a minimum of 99.995 % zinc.

- Special High Grade(SHG), high purity grade of zinc containing a minimum of 99.990 % zinc.

- Standard Specification for zinc(conform to the requirements prescribed in ASTM B6 ).

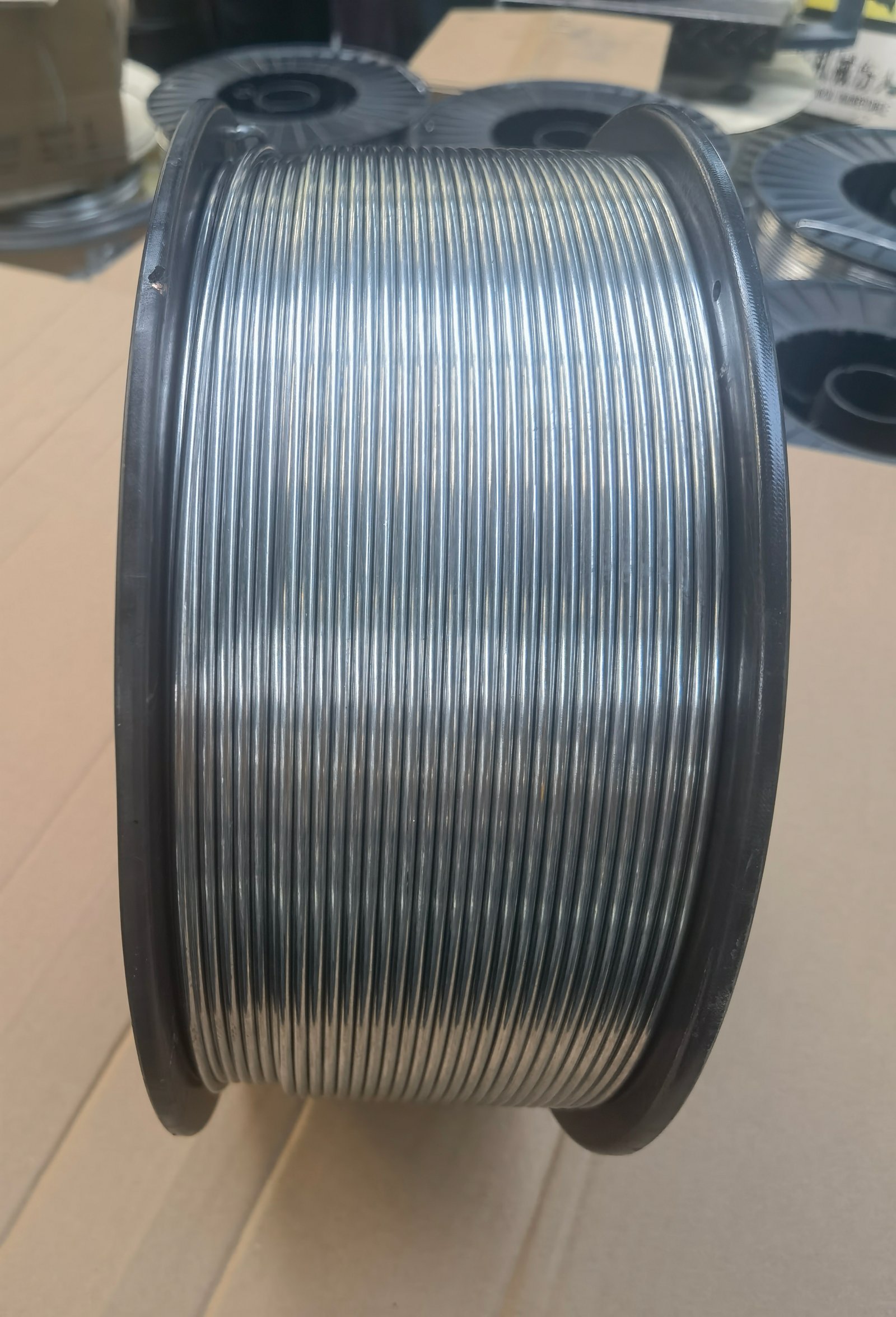

3. Surface properties

- The surface of the thermal spray wires shall be smooth and free of corrosion products ,slivers and splits,shrinkholes,splices and scales ,damages as well as neckings,welds and laps .

4. Dimensions and Permissible Variations

- zinc wire shall conform to the sizes, tolerances listed in ASTM B833( Table 1 ).

Click on Table 1 (ASTM B833).

| Nominal Wire Diameter | Permissible Variation | Nominal Wire Diameter | Permissible Variation |

| mm | mm | (in.) | (in.) |

| 4.763 | +0.0000,-0.0762 | (0.1875) | (+0.0000,-0.0030) |

| 3.175 | +0.0000,-0.0508 | (0.125) | (+0.0000,-0.0020) |

| 2.311 | +0.0000,-0.0381 | (0.091) | (+0.0000,-0.0015) |

| 2.000 | +0.0000,-0.0381 | (0.079) | (+0.0000,-0.0015) |

| 1.626 | +0.0000,-0.0381 | (0.064) | (+0.0000,-0.0015) |

| 1.448 | +0.0000,-0.0381 | (0.057) | (+0.0000,-0.0015) |

- zinc wire shall conform to the sizes, tolerances listed in ISO 14919: ( Table 2 ).

Click on Table 2 (ISO 14919)

| Site (mm) | Tolerance(mm) |

| 1.6 | +0 ; -0.05 |

| 1.62 | +0 ; -0.05 |

| 2.0 | +0 ; -0.06 |

| 2.3 | +0 ; -0.06 |

| 2.4 | +0 ; -0.06 |

| 2.5 | +0 ; -0.06 |

| 3.0 | +0 ; -0.07 |

| 3.17 | +0 ; -0.07 |

| 3.48 | +0 ; -0.07 |

| 4.76 | +0 ; -0.07 |

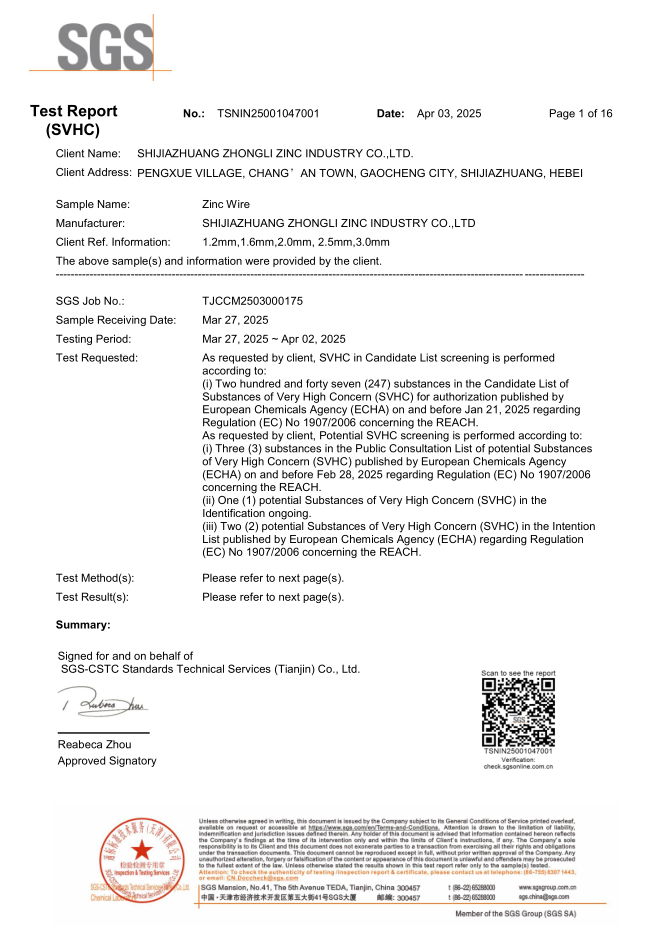

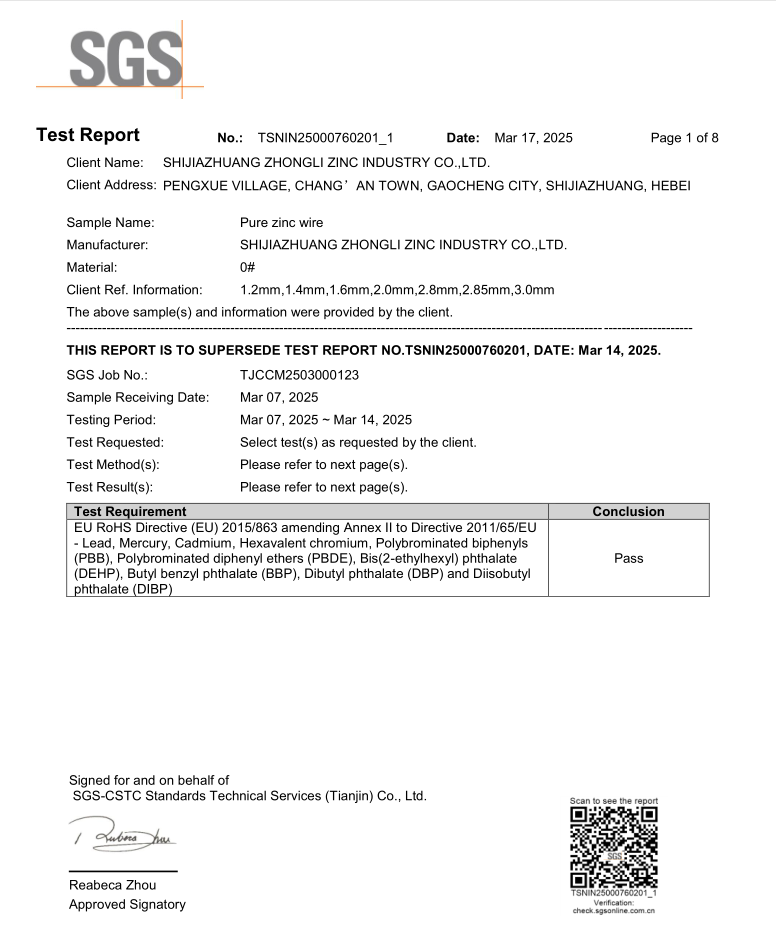

5. Chemical Composition

- Zinc wire shall conform to the requirements prescribed in ASTM B833 ( Table 3 ).

| Al % | Cd % | Cu % | Fe % | Pb % | Sn % | Other % | Zn % | |

| Common Name | max unless noted | max | max | max | max | max | Total max | min |

| 99.995% Zinc | 0.001 | 0.003 | 0.001 | 0.002 | 0.003 | 0.001 | 0.005 | 99.995 |

| 99.99% Zinc | 0.002 | 0.003 | 0.005 | 0.003 | 0.003 | 0.001 | 0.010 | 99.99 |

| 99.95 Zinc | 0.01 | 0.02 | 0.001 | 0.02 | 0.03 | 0.001 | 0.05 | 99.95 |

| 99.9 Zinc | 0.01 | 0.02 | 0.02 | 0.02 | 0.03 | ….. | 0.1 | 99.9 |

- Zinc wire shall conform to the requirements prescribed in ISO 14919: ( Table 4 )

| Symbol | Zn % | Pb % | Cd % | Pb+Cd % | Sn % | Fe % | Cu % | Other % | Total % |

| Common Name | min | max | max | max | max | max | max | max | max |

| Zn99.99 | 99.99 | 0.007 | 0.004 | 0.011 | 0.001 | 0.005 | 0.002 | 0.12 | 0.010 |

6. Physical Properties and Mechanical Properties (For reference only)

| Physical Properties | Zinc wire ( 99.99-99.9% ) | Mechanical Properties | Zinc wire ( 99.99-99.9% ) |

| Deasity | 6.92-7.16 g/cm³ | Ultimate Tensile Strength | 90-130 MPA |

| Nominal density | 7.14 g/cm³ | Nominal Ultimate Tensile Strength | 103 MPA |

| Melting Point | 420 ℃ | nominal tensile elongation(under load) | 50% |

7. Size(s) of Packaging

- the wire shall be a continuous length per spool, coil, or drum. Splices or welds are permitted, provided that they do not interfere with the thermal spray equipment or coating process.

- If special packaging is required, it shall be negotiated between the supplier and the purchaser.

| Packaging | Size | Weight |

| Coil | Outer diameter:420mm, Inner Diameter:290mm, Outer width:70m | 25kg/Coil |

| Reel/spool | Outer diameter:270/300mmmm, Hole diameter:50mm, Outer width:105 mm | 10-20kg/reel |

| Drum | Outer diameter:460mm Height:280mm | 30-50kg/drum |

| Drum | Outer diameter:570mm Height:380mm | 100kg/drum |

| Drum | Outer diameter:570mm Height:740mm | 200-250kg/drum |

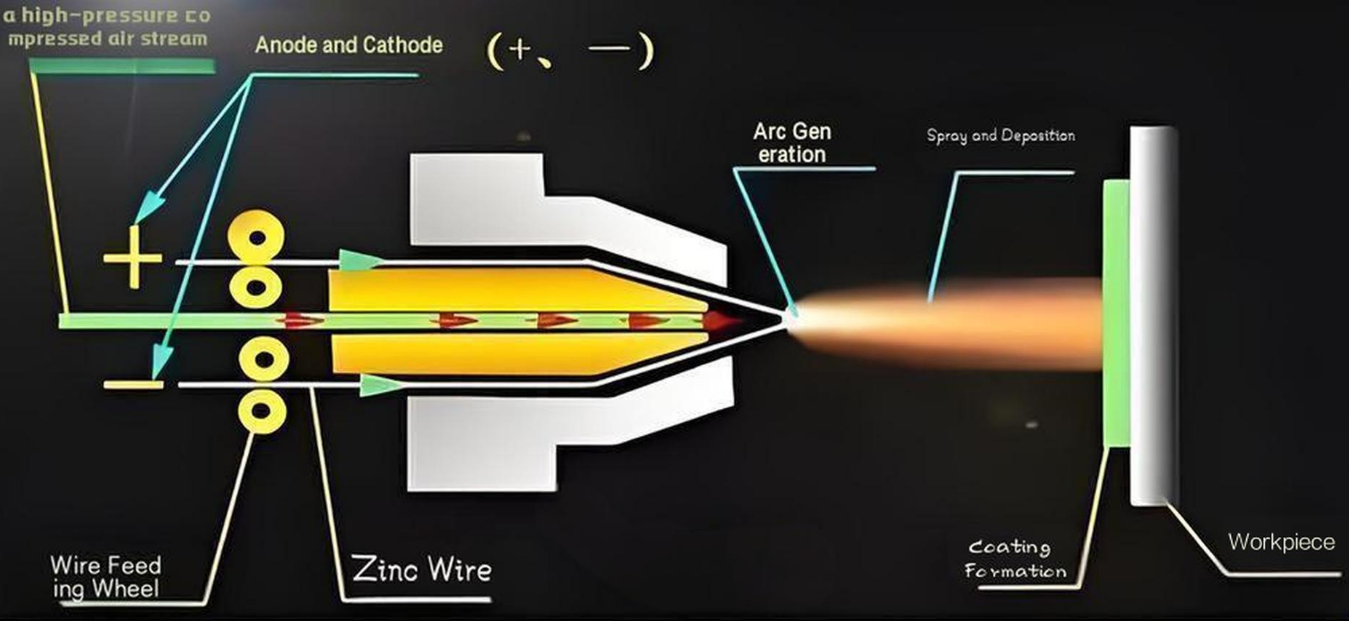

8. Purpose

Zinc wire is used in oxy-fuel and arc thermal spray equipment to deposit zinc coatings by thermal spraying (metallization) for corrosion protection of steel and iron.

Concrete application:

- Wind turbines, Hub,Base,Bearing seat,

- Capacitor.

- Heat exchanger.

- Cast pipe.

- Bridges.

- Locks & dams

- Above ground storage tanks

- Light poles