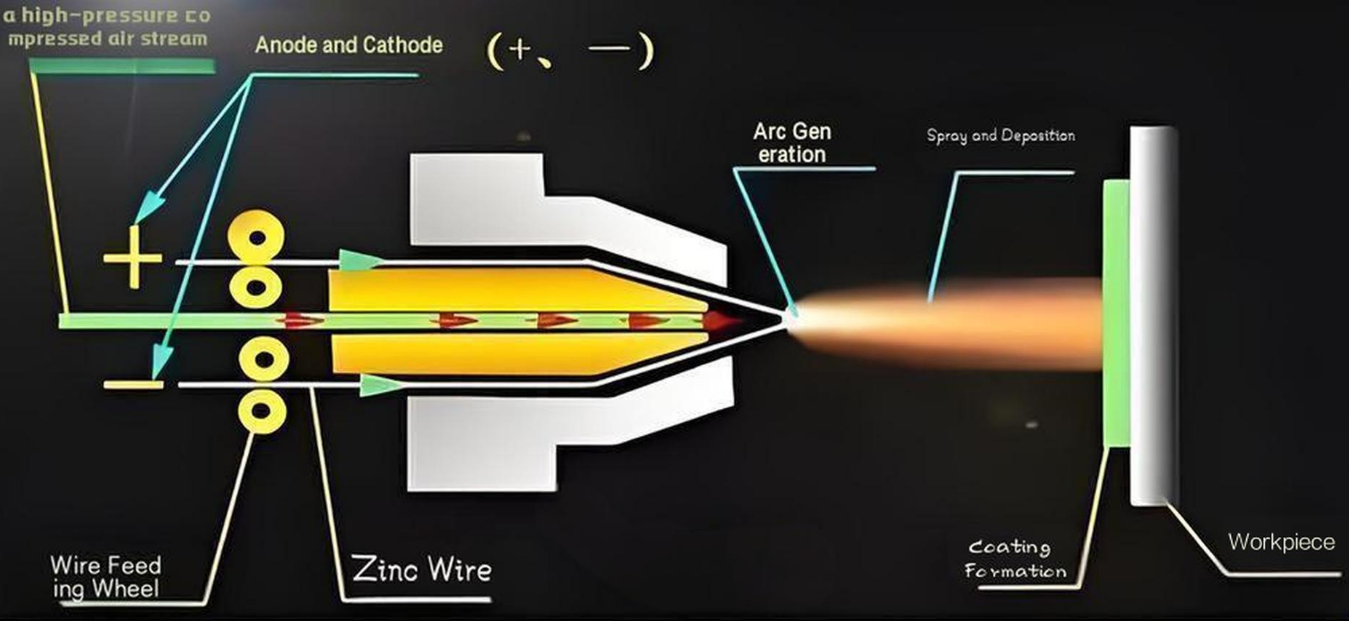

Trusted Zinc Wire Producer with 30 Years Expertise

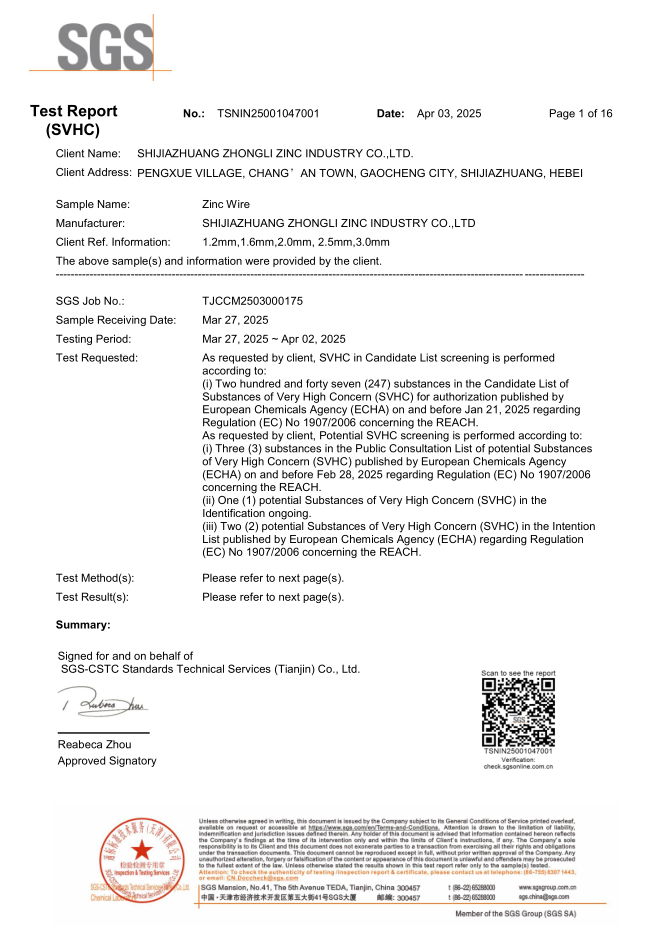

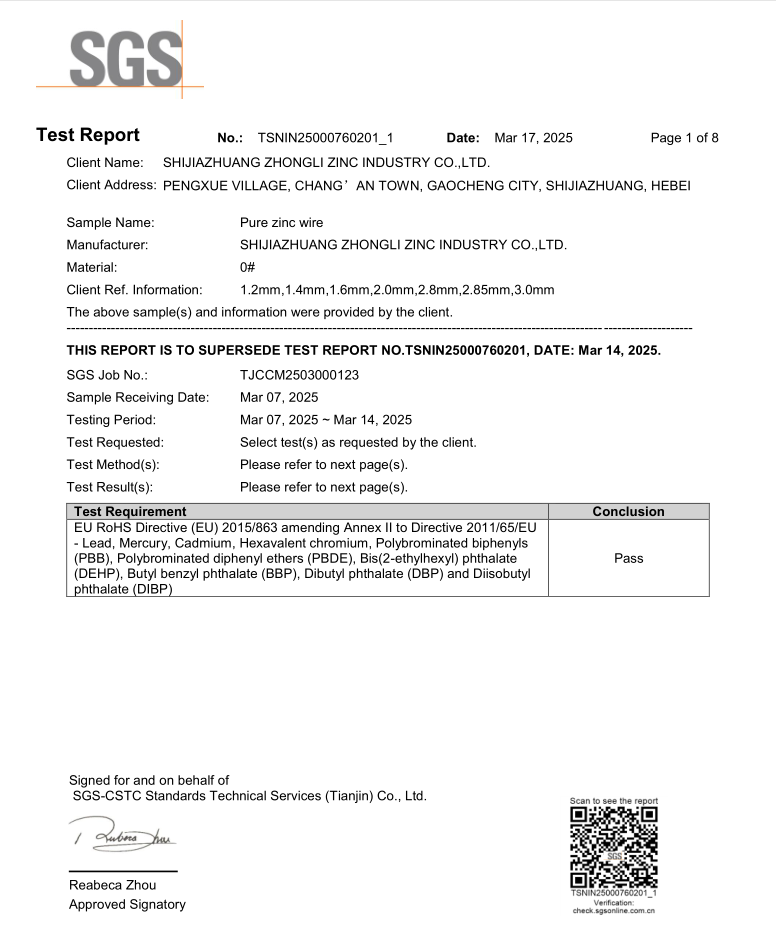

This product is fully compliant with: EU RoHS Directive REACH Regulation (EC)

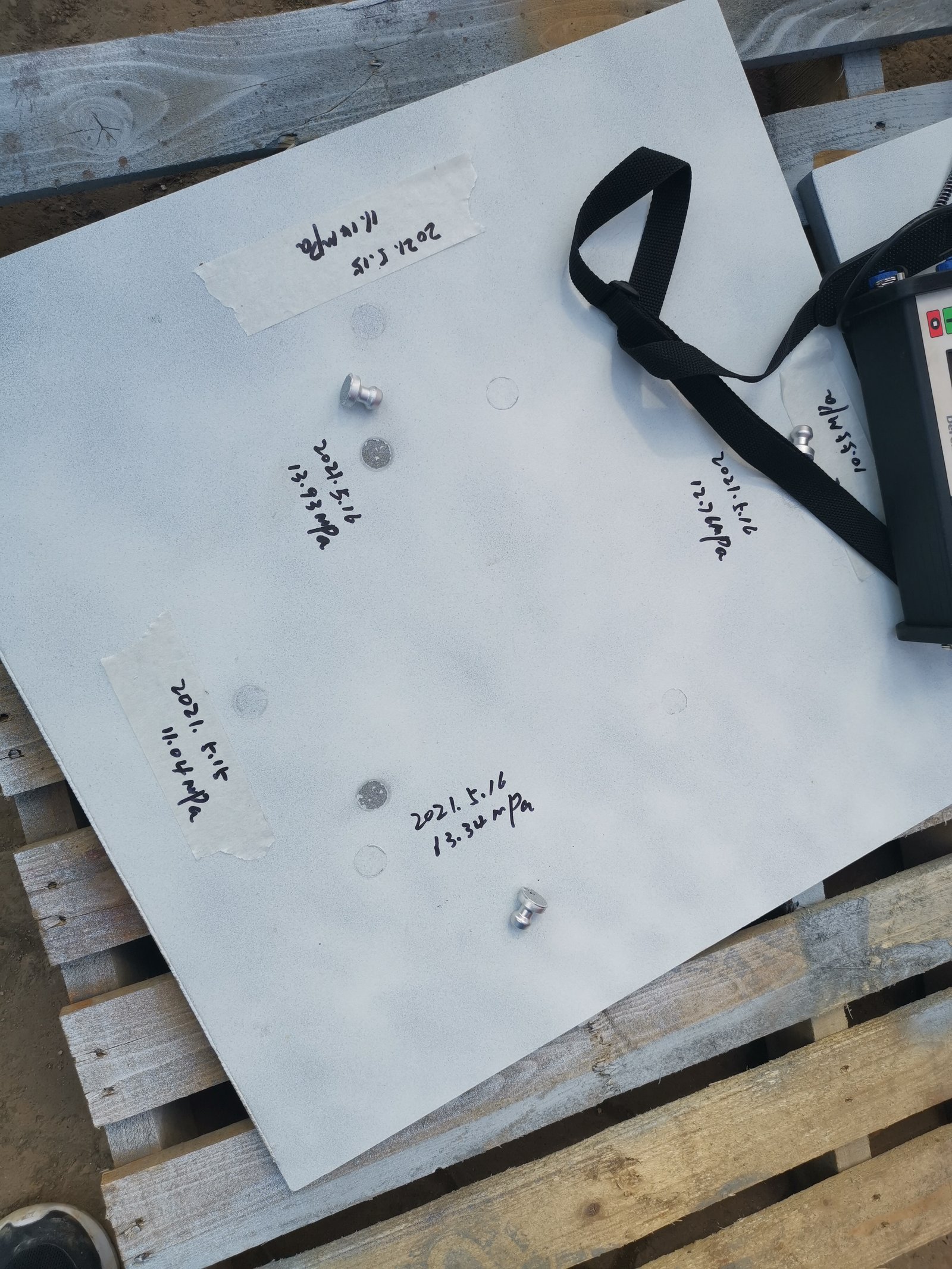

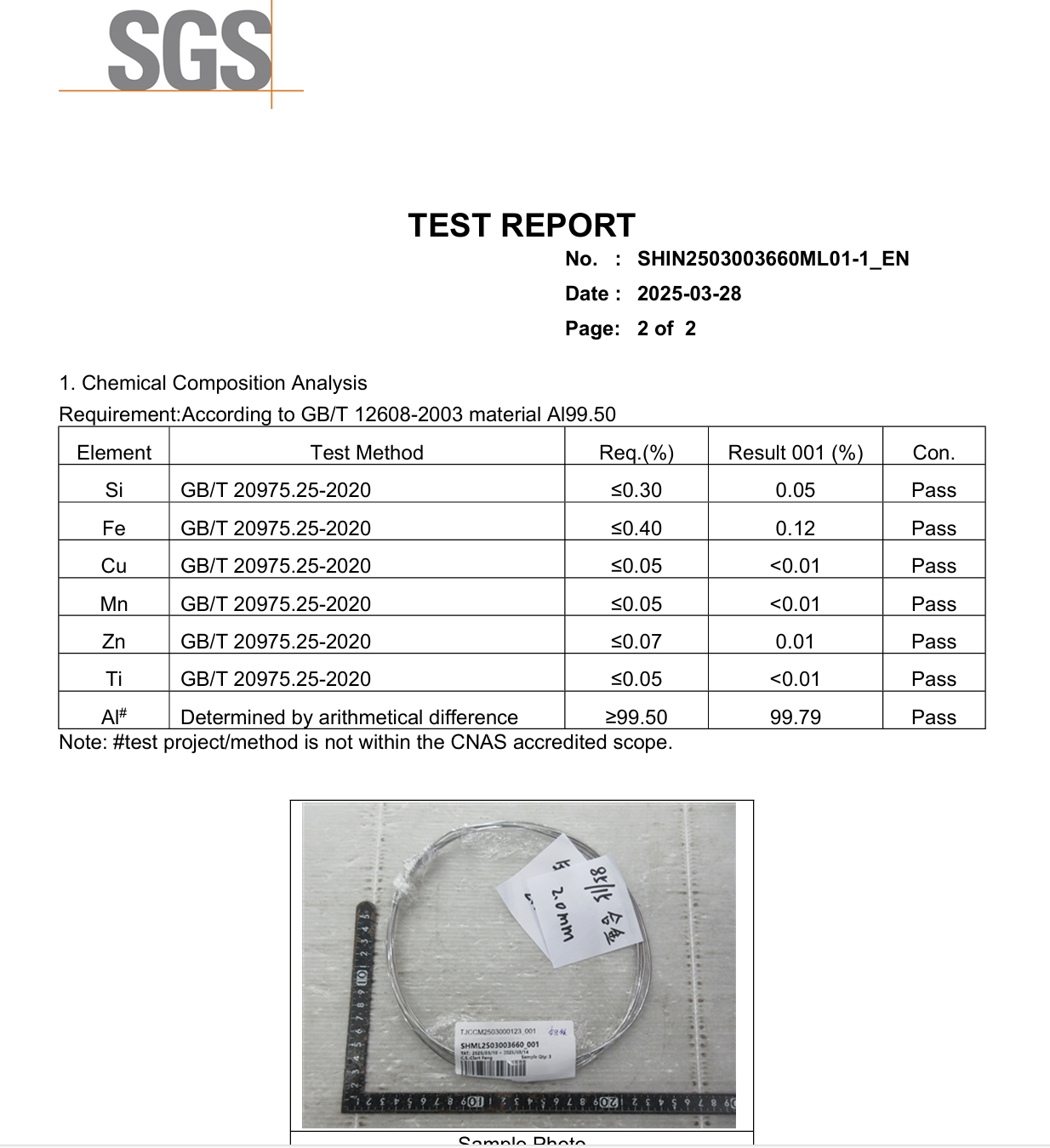

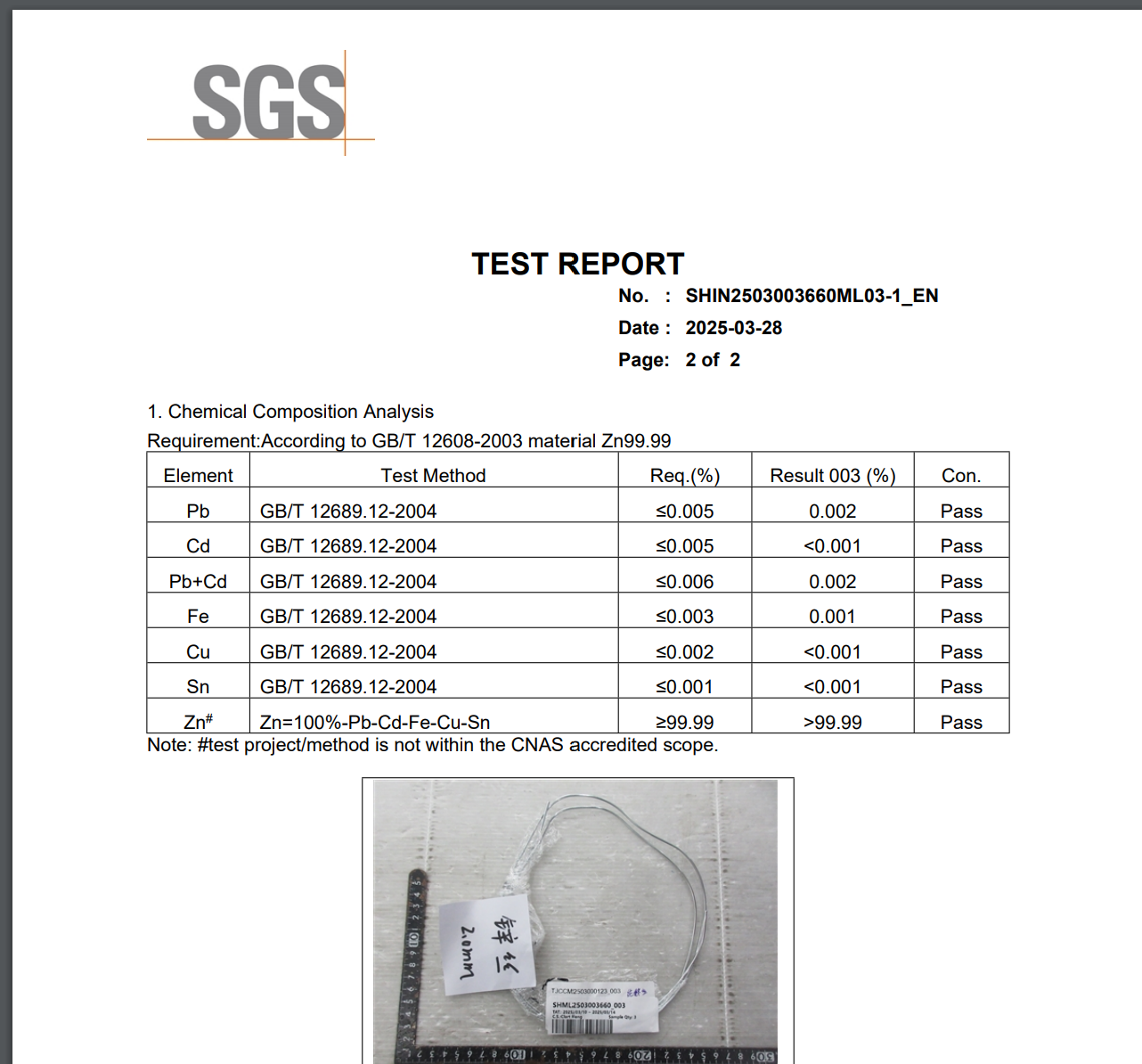

Precision Quality Control Guaranteed to Meet Your Specifications

This product is manufactured in full compliance with ISO 14919:2015,Zinc content ≥99.99%

We possess proprietary zinc wire manufacturing equipment and cutting-edge production technologies

Compliant with ISO 9001 for international quality assurance