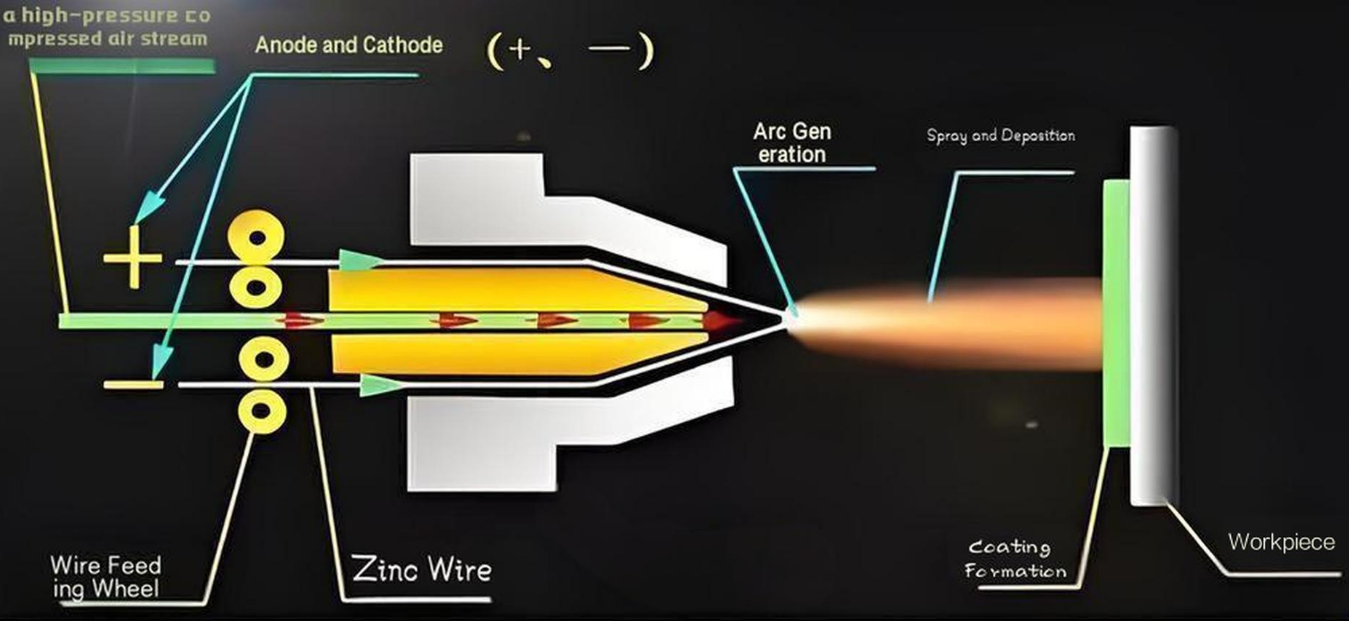

The arc spraying zinc wire process uses an electric arc as a heat source. The core process is as follows:

1.Wire Feeding and Electrical Conductivity: Two zinc wires are fed uniformly and continuously into the two conductive nozzles of the spray gun through a wire feeding mechanism. These two conductive nozzles are connected to the positive and negative terminals of the spraying power supply, respectively. Before the tips of the zinc wires come into contact, the system must ensure that they remain electrically insulated.

2.Arc Generation and Melting: When the tips of the two zinc wires come into contact, a short circuit occurs, triggering the arc. The high temperature generated by the arc instantly melts the zinc wire.

3.Atomization and Acceleration: Simultaneously, a high-pressure compressed air stream (or high-speed gas stream) acts on the arc melting zone, breaking up and atomizing the molten zinc metal into tiny molten particles (droplets).

4.Spray and Deposition: This high-speed gas stream simultaneously accelerates these atomized zinc droplets and sprays them onto the pre-treated workpiece surface.

5.Coating Formation: The molten zinc particles rapidly cool, flatten, and deposit in layers upon impact with the workpiece surface, ultimately forming a dense zinc coating.

Therefore, the entire arc spraying process is essentially a continuous, cyclical sequence of melting, atomization, and deposition steps.